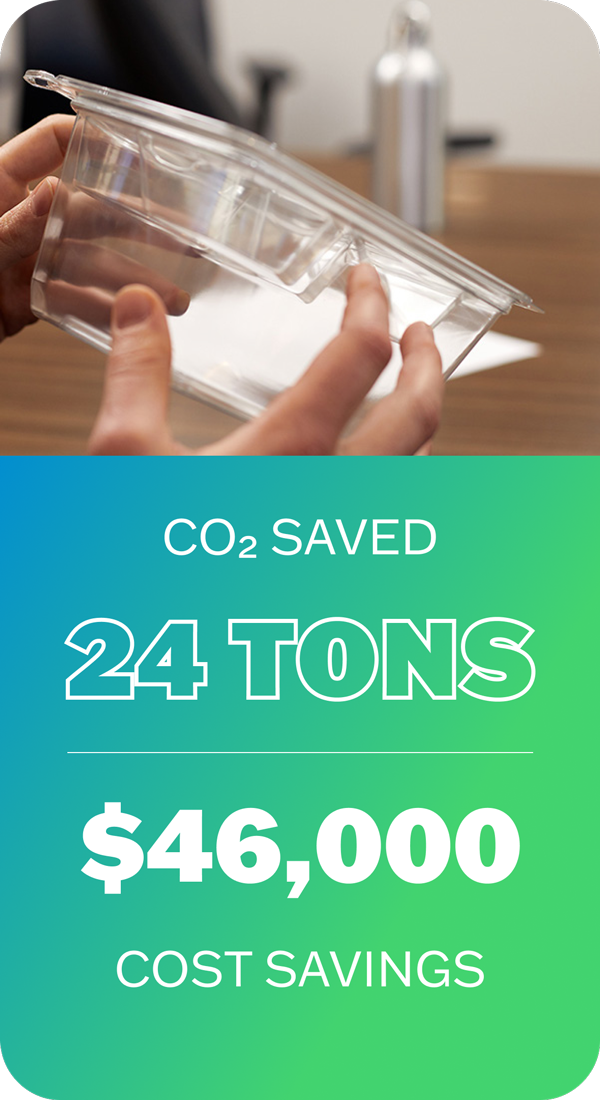

Our Vision

At Display Pack, we believe that our responsibility extends beyond providing exceptional products. We firmly believe that embracing sustainable practices in every aspect of our business is the key to creating a positive impact on the world around us, enabling us to empower people and drive meaningful change.

By fostering a culture of sustainability and encouraging collective action, we envision a future where both business and our planet can thrive.